In the realm of stone fabrication, the bridge saw machine stands as a beacon of precision and efficiency. This article delves deep into the intricacies of this indispensable tool, exploring its features, benefits, and applications. Whether you're a seasoned professional or a novice in the industry, this guide will provide you with comprehensive insights into the world of bridge saw machines.

Stone Bridge Saw Machine

A stone bridge saw is a specialized machine used primarily in the stone fabrication industry. It is designed to cut large stone slabs into precise shapes and sizes. The machine consists of a sturdy bridge structure, a diamond blade, and a motorized system that moves the blade across the stone surface.

Stone Bridge saw machine is a type of stone cutting machine designed for diversified stone business. And CNC stone bridge cutters are cutting machines made for cutting natural stone, granite, marble, and ceramics. With a CNC stone saw, it is good at special-shaped cutting, polishing, edging, drilling, and chamfering of granite, marble, quartz, artificial stone, and natural stone. Therefore, it is also known as stone bridge saw cutting machine, stone bridge saw for quartz, bridge saw for granite, tile bridge saw, marble bridge cutting machine, stone bridge saw cutter, etc.

5 Axis Bridge Saw Machine

5 axis CNC bridge saw is an automatic stone machining equipment that can complete the processing of pentahedron special-shaped curved surfaces at one time through five-axis linkage control, that is, three linear moving axes and two rotating axes.

It is a type of Automatic CNC Machine tailor-made for the majority of stone fabricators by IGOLDENCNC in order to meet the cutting plans of stone machining manufacturers. It has various processing modes of cutting, milling, engraving, and drilling. The bridge saw features with multiple functions, small footprint, simple operation, precise cutting, quick and convenient conversion of different functions.

4 Axis Bridge Saw

A 4 Axis Bridge Saw is a type of CNC (Computer Numerical Control) machine used for cutting various materials, such as stone, granite, marble, and ceramic tiles. It is equipped with four axes of movement, allowing for precise and efficient cutting in multiple directions. The additional axis provides increased flexibility and versatility in cutting different shapes and angles.

Stone Bridge Saw Advantage

- Using automatic touch human-machine interface, intuitive operation, simple and convenient;

- Main core control component USES the first-line brand, stable performance and long life;

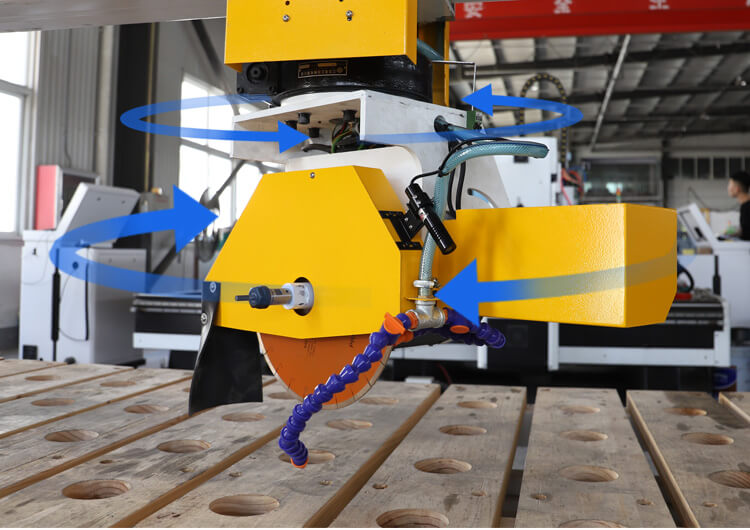

- Can spin 0 ° to 360 ° and 90 ° inclined processing, used in any direction and any Angle of the cutting;

- Implementation heterosexual complex surface machining, cutting, milling, drilling and multi-function in one;

- Increase other optional features, such as photo function layout, automatic measuring plate thickness, automatic pressure material, etc.

Applications of Stone Bridge Saw:

- Kitchen countertops: The machine is commonly used for cutting stone materials to create custom kitchen countertops with precise dimensions and shapes.

- Vanity tops: It is also used in the fabrication of bathroom vanity tops, ensuring accurate cutouts for sinks and faucets.

- Architectural projects: The 4 Axis Bridge Saw is utilized in architectural projects that require precise cutting of stone materials for various applications, such as flooring, wall cladding, and decorative elements.

Features and Functionalities of CNC Stone Bridge Saw

- Bridge Structure: The saw gets its name from the bridge-like structure that spans the cutting area. The bridge is mounted on rails and moves horizontally along the length of the machine, while the stone slab remains stationary on a worktable.

- Diamond Blade: A high-quality diamond blade is mounted on the bridge and rotates at high speeds to cut through the stone slab. Diamond blades are specifically designed to handle the hardness and abrasiveness of stone materials.

- Cutting Dimensions: Stone bridge saws can handle large stone slabs of varying sizes and thicknesses. The cutting dimensions depend on the specific model and can range from small countertop-sized slabs to larger architectural pieces.

- Cutting Accuracy: The bridge saw features precise control mechanisms that allow for accurate cuts. It may have a computerized numerical control (CNC) system that enables operators to program specific cutting paths, dimensions, and angles.

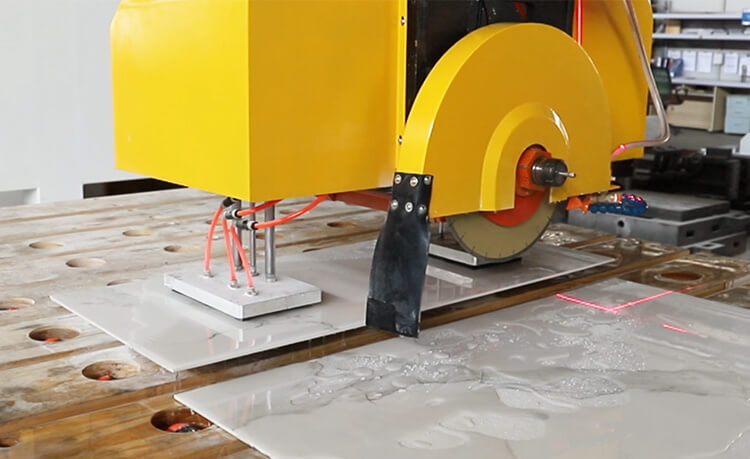

- Water Cooling System: Cutting stone generates heat, so most bridge saws have a water cooling system to keep the diamond blade cool and minimize the risk of overheating.

- Worktable and Slab Support: The worktable provides a stable surface for holding the stone slab in place during cutting. It may have adjustable clamps, suction cups, or other mechanisms to secure the slab and prevent movement or vibrations.

- Slab Handling and Loading: Some bridge saws have additional features for slab handling, such as motorized tables or hydraulic lifters, to assist with loading and unloading heavy stone slabs safely.

- Dust Collection: Stone cutting generates a significant amount of dust, so many bridge saws include dust collection systems to minimize airborne particles and maintain a clean working environment.

- Operator Controls: The machine typically has a control panel that allows operators to set cutting parameters, monitor the cutting process, and make adjustments as needed.

Intelligent five-axis bridge cutting machine is a comprehensive five-axis processing equipment. It has the function of taking photos, positioning and typesetting, automatic measurement of plate thickness and tool size, and the head can rotate 360 degrees.

Cutting, edging, chamfering, digging and other multi-functional intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. Besides cutting modeling, it can also open material for large plate, 45 degree chamfering, open basin hole, stove hole, and slash line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!It can implement different complex curved surface processing and combines the functions of cutting, drilling, milling, engraving into an oganic whole.

CNC Stone Cutting Bridge Saw Detail

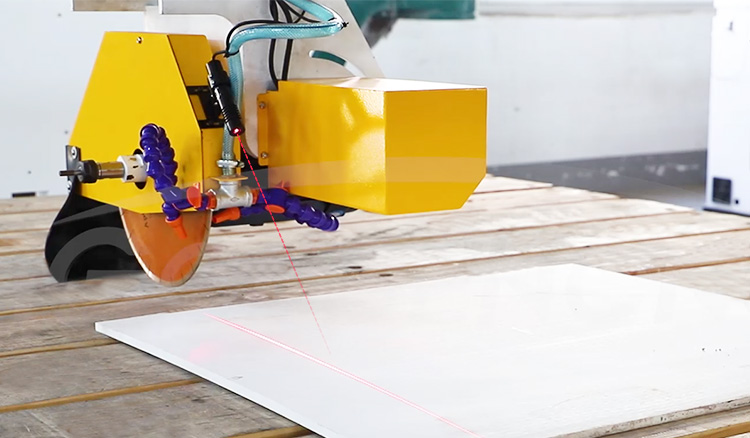

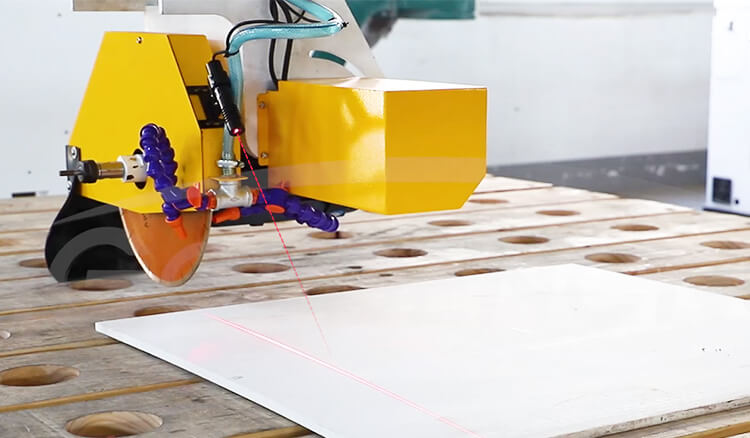

Infrared Localization,convenient to observe and adjust.

The machine head automatically flips ±360 degrees

The worktable can be turned left and right for easy loading and unloading

The machine head can move the plate, which is more convenient.

•Fully automatic touch screen Cutcam system

Striker plate Swage setting Camera function

(Option)3D Kitchen Bathroom Countertop Measuring Scanner with Laser Templator

|

Technical indicators |

parameter |

|

Model |

iGS-B-3320 |

|

Stroke of X axis |

3700mm |

|

Stroke of Y axis |

2000mm |

|

Z-axis stroke 1 |

255mm(Blade Diameter 400mm) |

|

Z-axis stroke 2 |

195mm(Length of milling cutter 40mm) |

|

A axis |

90° |

|

C axis |

360° |

|

Saw blade motor power |

7.5W / 15KW |

|

Blade Diameter |

400mm |

|

Input power |

Single-phase AC 220V 50-60Hz 10A |

|

Dimensions |

5845mm(L)*3922mm(W)*3687(H)mm |

|

Total weight |

4300kg |

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations.

Popular applications include:>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.